How We Work

Industrial batteries only create value when they’re correctly sized, safely installed, smartly controlled and continuously optimised.

Our goal is not to sell as many batteries as possible,

but to design the optimal solution for each company,

so the profitability of every installation is maximised.

Why businesses choose InduBa’s process?

Lower energy costs

via peak shaving and higher self-consumption.

Extra revenue

from grid balancing, day-ahead markets and dynamic tariffs.

Safety & reliability

through solid engineering, water-cooling, fire detection and certified hardware.

Predictable returns

with data-driven sizing, subsidies and ongoing optimisation.

Lean team, direct contact

short lines, open and clear communication.

Competitive, factory-direct pricing

independent advice with access to multiple manufacturers and transparent pricing.

Contact us

for a personal calculation or full business case — battery-only or battery + solar.

Our Proven Roadmap to Success

From first intake to a fully operating system — a structured workflow that keeps every step clear.

Intake & data collection

- Optional NDA and data access permissions.

- Collect 12–24 months of bills plus interval data (15-minute).

- Gather info on PV, EV chargers, machinery, grid connection and tariff structure.

Output: clear overview of the current situation, expected opportunities and data completeness.

Discovery call

- Understand energy goals, business constraints and timelines.

- Prioritise use-cases: peak shaving, PV shift, balancing, backup, fast charging.

- Initial compliance scan (standards, fire code, zoning, Synergrid/AREI/VDE).

Output: short Project Charter with scope, goals and next steps.

Energy scan & feasibility

- Analyse bills and load profile; install temporary meters if needed.

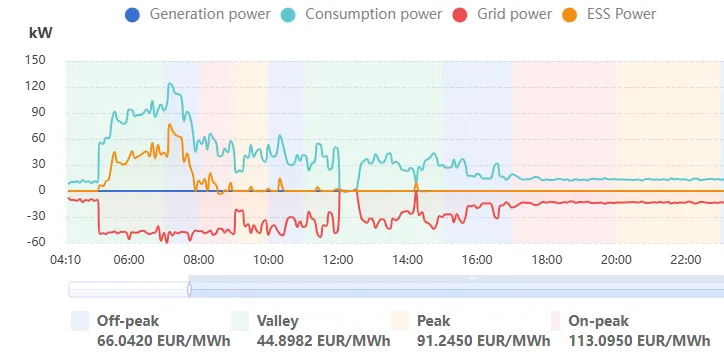

- Run scenarios for costs & revenues: peak tariffs, PV surplus, balancing income, dynamic pricing.

- Sensitivity analysis for energy prices, expansion and load growth.

- Grid pre-check together with the DSO.

- Cyber/IT requirements: remote access, telemetry and security.

Output: Feasibility Note with recommended battery size (e.g. 64 kWh to 4 MWh+), business case and estimated ROI.

➝ Decision Gate 1: Go / No-Go

Proposal & quote

- Technical design: battery, inverter, EMS, switchgear and safety.

- Revenue stacking plan: peak shaving, PV shift, day-ahead & imbalance markets, FCR/FRR.

- Optional PV integration: design and installation if economically attractive.

- Financial model: CAPEX, OPEX, degradation, payback, NPV and IRR.

- Subsidies & financing: VLAIO, STRES, VLIF (agriculture), leasing or BESS-as-a-Service.

Output:

➤ Technical proposal

➤ Commercial quote

➤ Investment timeline

➤ Risk & mitigation list

➝ Decision Gate 2: Go / No-Go

Installation & commissioning

- Civil works (e.g. concrete foundation and cable routing).

- Installation of batteries, inverter, EMS and fire detection/suppression.

- AC/DC integration, protection studies and switchgear by certified Belgian cabinet builder.

- Factory Acceptance Test (FAT) plus Site Acceptance Test (SAT).

Output: system online, tested, documented and ready for operation.

Evaluation & optimisation

- Verify KPIs: peak reduction, self-consumption, revenue, cycle efficiency.

- Adjust EMS rules: pricing triggers, SoC strategy, PV curtailing, fail-safe modes.

- Optional add-ons: EV charging optimisation, backup modes, solar expansion.

Output: Optimisation report with improvements for extra return.

Monitoring & optimisation

- 24/7 monitoring of performance, alarms and safety parameters.

- Optimisation of charging/discharging strategy based on dynamic tariffs and usage.

- Regular reporting on savings, revenues and battery health.

Output: continuous performance improvement and transparent reporting.

Optional: Integrated Solar (PV)

If required, InduBa also designs and installs PV.

- Maximises self-consumption

- Reduces curtailing

- Avoids peak tariffs

- Increases annual savings

Deliverables you receive

- Project Charter

- Feasibility Note + M&V plan

- Technical proposal + TCO model

- FAT/SAT reports & certificates

- As-built drawings, O&M manual + user training

- Monthly dashboard + annual performance review

KPIs we track

- Peak reduction (kW)

- Self-consumption (%)

- Market revenue (€/kW-year, €/MWh)

- Round-trip efficiency

- EMS uptime

- Battery health & cycle count

Safety & compliance

- EN/IEC 62933 standards

- Water-cooling for longer lifespan

- Fire detection + suppression

- Certified Belgian switchgear

- Safe-shutdown logic and fallback modes

- Grid code compliance (Synergrid / AREI / VDE)

📞 Want numbers for your company?

Contact us for a personal calculation or business plan — battery-only or

battery + solar.

We analyse your consumption and grid data, simulate savings & revenues, and deliver a clear

investment plan with payback and IRR.